The urbanization trend will create opportunities for greater collaboration between the mining and construction industries.

Image source:Getty Images/ Markus Thoenen

Debojyoti Roy

Chief Corporate Strategy and Planning Officer at Tata Steel

Population growth and ongoing urbanization are driving the expansion of global megacities. By 2050, the number of megacities worldwide is expected to approach 50.

Minerals and metals play a critical role in the construction process, and the mining industry will support urban development.

Suppliers of critical metals like steel must meet the growing demand for infrastructure while simultaneously addressing challenges such as carbon reduction and digitalization.

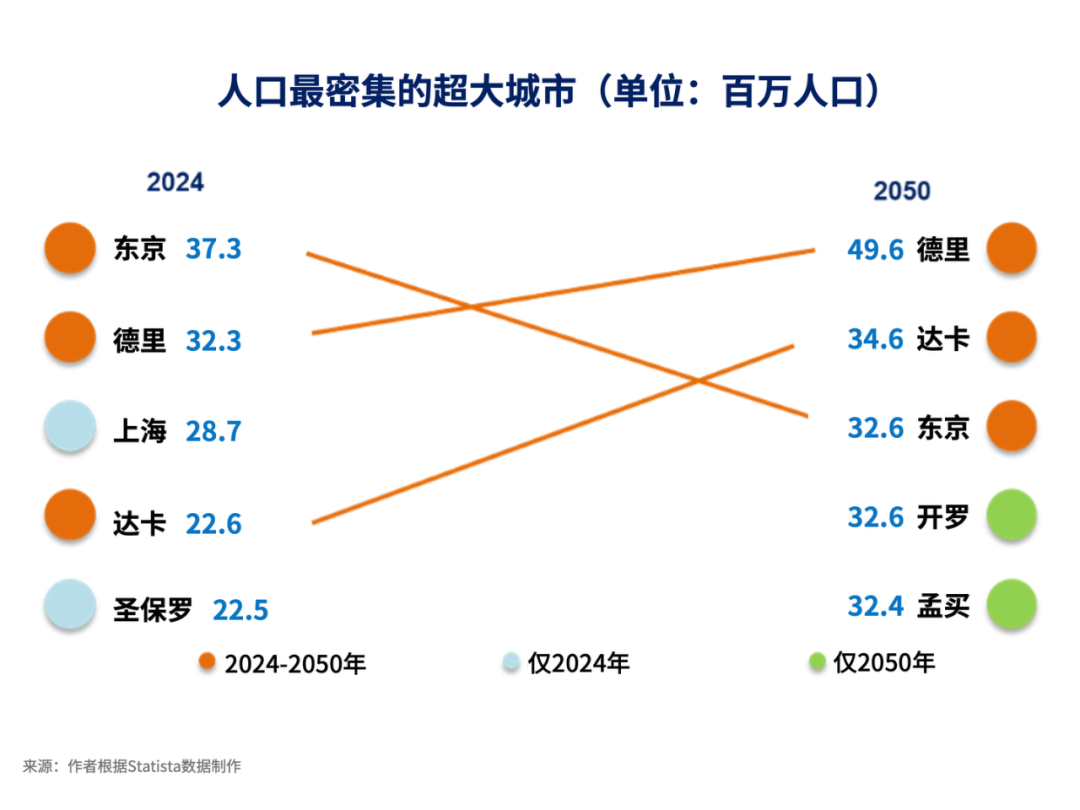

By 2050, the world’s 1,000 largest and most prominent cities will see their populations grow by more than 500 million people. Emerging nations in Africa and the Asia-Pacific region will experience exponential population growth, while many cities in China, Europe, and the developed areas of the Asia-Pacific region are expected to stabilize in terms of population size.As population growth and ongoing urbanization continue, the global urban population will rise from 54% in 2020 to 70% by 2050. Currently, there are 33 megacities worldwide. By 2050, an additional 14 megacities are expected to emerge, adding approximately 213 million people to the urban population.Image source:The author created this based on Statista data.

Economic growth, particularly in developing countries, will accelerate urbanization and fuel the expansion of megacities, driving a rapid increase in the global population. As a result, the global demand for infrastructure development and construction is expected to remain strong. Minerals and metals play a critical role throughout the building process, and as urban populations continue to grow worldwide, these materials will need to evolve to meet emerging needs.

New Trends in Architecture and Key MaterialsUrbanization and the influx of urban populations are driving growth, spurring innovation, and giving rise to new construction methods. This transformation has created a growing demand for cutting-edge techniques, such as modular construction—where building components are prefabricated off-site and then transported to the final location for assembly. This approach not only allows for greater flexibility in design and layout but also significantly speeds up the construction process compared to traditional methods. Another emerging trend is lean construction, which helps building firms enhance both process efficiency and quality while minimizing waste to the greatest extent possible.As these trends unfold, rapidly expanding cities are introducing new standards and requirements, driving the construction supply chain to evolve continuously and become more collaborative. Meanwhile, global warming—and the construction industry’s significant contribution to greenhouse gas emissions—has intensified the demand for sustainable, recyclable materials. Finally, emerging digital trends and shifting workforce dynamics are accelerating the adoption of artificial intelligence (AI), machine learning (ML), robotics, and other cutting-edge digital tools across the industry.In this context, the mining industry and metals play a critical role in modern construction, enabling sustainable, resilient, and efficient building practices. They are versatile, highly adaptable, and easy to shape for optimal space utilization, paving the way for innovative, eco-friendly production methods.For example, steel is the backbone of the construction industry. As cities expand and demand robust, long-lasting infrastructure grows, steel becomes especially critical. Steel-intensive designs enable scalable, modular construction solutions as well as advanced energy systems—and thanks to recycling and reuse, steel can even support a circular economy. In countries like India, where the construction and infrastructure sectors could account for 69% of steel demand by 2034, high-strength steels that offer superior toughness, formability, and weldability are emerging as essential materials. Meanwhile, steel producers are increasingly adopting greener manufacturing technologies to tackle global emissions challenges.Aluminum is favored for its lightweight, high strength, and corrosion resistance, making it ideal for flexible, aesthetically pleasing, and recyclable architecture. It also boasts excellent formability and durability, aligning perfectly with the growing global shift toward sustainable building practices.Copper is also an indispensable material, prized for its durability, antibacterial properties, fire resistance, and corrosion resistance—qualities that are critical to building safety. The construction industry accounts for nearly half of all copper consumption. As copper usage grows in energy-transition technologies like solar power, demand for the metal is expected to rise further.Other materials, such as carbon fiber, can be used to reinforce concrete and enhance the durability of structures. Carbon fiber’s strength, corrosion resistance, and lightweight properties make it ideal for cost-effective, eco-friendly construction methods.Suppliers of critical metals such as steel, aluminum, and copper need to adjust their processes to meet the rapidly growing demand from the infrastructure sector. As carbon reduction efforts and digital transformation increasingly reshape the industry, suppliers must adapt their assets, processes, and systems to effectively address these evolving challenges.This is crucial not only for the industry but also for broader economic development. The construction sector, which includes builders, developers, suppliers, and contractors, is closely intertwined with the wider economy. In India alone, the market for construction tools and machinery is already worth a staggering $14 billion. Moreover, the production of key materials like steel, cement, and timber is highly labor-intensive and spans extensive value chains involving industries such as metals and logistics, generating an annual economic value of $25 billion.Addressing Challenges in the Construction IndustryDue to urbanization and the continued growth of megacities, demand for construction services is rising—but the industry also faces several challenges. The metals and mining sectors can play a crucial role in helping address some of these issues.Talent shortages, AI and digital adoption, and declining numbers of new employees—issues that are impacting productivity, efficiency, and worker safety—are today’s key concerns in the construction industry. To tackle these challenges, the industry is considering hiring more data scientists and software developers.Key construction materials like steel and cement contribute significantly to greenhouse gas emissions. Global manufacturers of these materials must prioritize asset restructuring, invest in new assets and processes, and adopt sustainable practices that emphasize material recycling and emission reductions. Meanwhile, investments, policy initiatives, partnerships, and collaborations are gradually driving the growth of a greener steel industry.The construction industry is shifting from tactical procurement—focused on staying within budget—to strategic procurement. The strategic procurement model simplifies processes, enhances value, and fosters an ecosystem that includes strategic suppliers and partners. This approach helps mitigate ongoing cost pressures and supply chain risks, while also enabling companies to meet growing customer demands—and the increasing needs for skilled labor, materials, and technology-driven partnerships.Metal and mineral suppliers must collaborate with the construction industry to support the growing trend of strategic procurement. To achieve this, suppliers can develop integrated supply chain solutions, offer more transparent digital platforms, and adopt flexible contract models. Such initiatives will streamline logistics, foster data sharing to enhance sustainability and compliance, and help stabilize costs amid market volatility. By simplifying complexities, mitigating supply chain risks, and building more resilient partnerships, construction companies stand to benefit significantly.4. Intelligent OperationsThe industry is deploying Industry 4.0 technologies such as Building Information Modeling (BIM), AI and machine learning, digital twins, and remote project monitoring using sensors, robotics, and drones. These advancements enable data-driven decision-making, facilitate dynamic scheduling, and help minimize budget and schedule deviations—often across multiple sites.Metal suppliers can collaborate in their digital transformation by sharing data and knowledge. This will help optimize scheduling and maintenance systems, enhance visibility and operational efficiency across the building’s entire lifecycle, and ultimately boost overall process effectiveness.5. Prefabricated and Modular ConstructionPrefabricated and modular buildings can optimize design, enhance quality control, and reduce lead times. However, this requires building a strategic ecosystem that fosters collaboration among suppliers and partners, as well as evaluating the long-term manufacturing process. Manufacturers of flexible and highly adaptable metals and materials—such as steel and aluminum—will play a critical role in this ecosystem, helping to meet the growing demand for modular construction.Building the megacities of the futureUrbanization and the resulting surge in infrastructure demand are bringing diverse changes and growth opportunities to the construction industry.In addition to emerging trends like modular, lean, and sustainable construction, digitalization is also reshaping the construction industry. Metal and materials suppliers are developing cutting-edge technologies, while the construction sector is proactively addressing future challenges through key strategies such as digital advancements and collaborative partnerships with suppliers.Collaboration between the construction industry and suppliers of metals and materials such as steel, aluminum, and copper will ensure that industries can adapt to and benefit from emerging economic trends.The above content solely represents the author's personal views.This article is translated from the World Economic Forum's Agenda blog; the Chinese version is for reference purposes only.Feel free to share this in your WeChat Moments; please leave a comment below if you'd like to republish.

Translated by: Di Chenjing | Edited by: Wang Can

The World Economic Forum is an independent and neutral platform dedicated to bringing together diverse perspectives to discuss critical global, regional, and industry-specific issues.

Follow us on Weibo, WeChat Video Accounts, Douyin, and Xiaohongshu!

"World Economic Forum"