The cement industry generates enormous amounts of carbon dioxide emissions.

Image source:Unsplash/CHUTTERSNAP

Michael Purton

Senior Writer for the Forum Agenda

Global cement production accounts for approximately 8% of the world's total carbon dioxide emissions.

At the current rate of development, emissions from this industry are set to surge to 3.8 billion tons annually.

A new report from the World Economic Forum outlines four key decarbonization pathways for the cement and concrete industry.

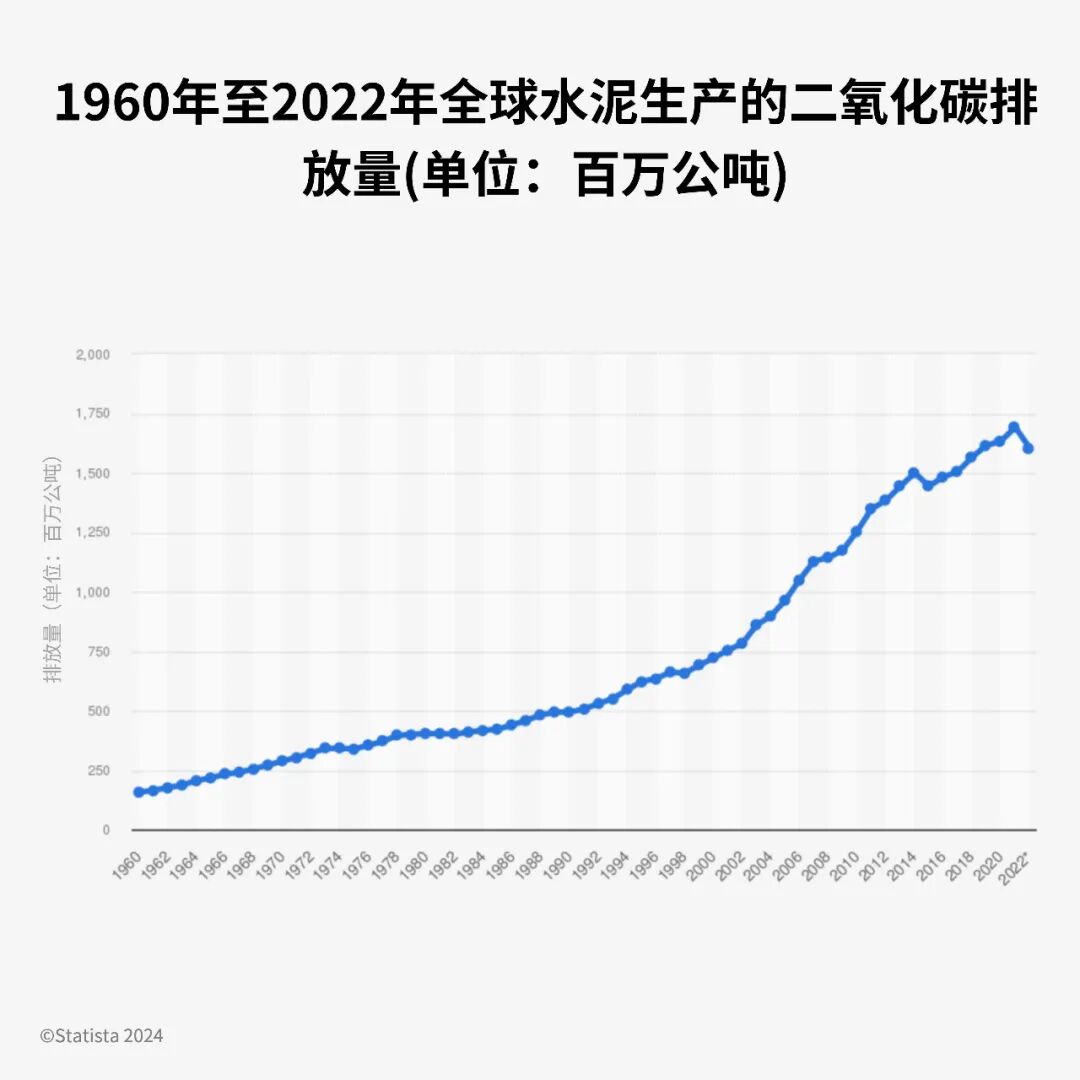

It is said that if the cement industry were a country, it would rank as the world's third or fourth-largest carbon dioxide emitter. In 2022, global cement manufacturing produced 1.6 billion metric tons of CO₂—accounting for roughly 8% of the world's total CO₂ emissions.Reducing carbon emissions from the cement production process is crucial for achieving global climate goals.Since the beginning of this century, emissions from cement production have more than doubled.

Image source:Statista

Of course, cement is the key ingredient in concrete—so an obvious solution would be to reduce the amount of concrete the world needs. But concrete is the second most widely used material after water, and as global urbanization and demand for infrastructure continue to rise, its annual global production is expected to grow from the current 14 billion cubic meters to 20 billion cubic meters by mid-century.Under the current approach, this trajectory would push the industry's annual carbon dioxide emissions soaring to 3.8 billion tons.A recent insights report jointly released by the World Economic Forum’s Pioneers Community and Deloitte highlights that, unlike other industries, more than half of the emissions from cement and concrete production stem from process emissions—whereas in most other sectors, energy-related emissions account for the majority. As a result, the industry must either develop innovative solutions tailored to this age-old sector—or rely heavily on carbon capture technologies.Here are four key decarbonization pathways for the cement and concrete industry, along with innovative solutions that contribute to each approach:Clinker is the primary ingredient in cement and generates extremely high carbon emissions, accounting for 90% of total cement-related emissions.Replacing clinker with lower-carbon auxiliary cementitious materials can directly address process-related emissions, but currently, there is no commercially viable solution available that can fully replace clinker on a large scale.However, there are already many proven methods that can significantly reduce the amount of clinker needed to produce cement and concrete. Among the most promising solutions is LC3 (Limestone Calcined Clay Cement), which can cut CO2 emissions by approximately 40% compared to traditional cement.LC3 addresses two sources of carbon emissions in the clinker production process. First, it replaces half of the clinker with calcined clay and ground limestone—materials that do not release carbon when heated, unlike traditional limestone. Second, the clay is heated at a lower temperature, significantly reducing the amount of fuel required. This means fossil fuels can be partially or fully replaced by electricity.Elsewhere, scientists at Cambridge University have developed a "zero-emission" technology to produce cleaner clinker.Their alternative process involves repurposing cement slurry from demolished buildings—whose chemical composition is identical to limestone—which, according to scientists, could cut carbon emissions by up to 3 billion tons annually.2. As a substitute for limestoneHeating limestone to produce clinker accounts for 50% of cement production emissions.Therefore, substituting limestone with alternative chemicals and processes during clinker production is an important method for reducing emissions.U.S. company Brimstone has developed a process that uses carbon-free calcium silicate rock—found in abundance on the surface of every major continent—to replace limestone in cement production.The company stated that its process can also remove carbon dioxide from the air, as the rocks it uses contain magnesium, which can passively and permanently capture CO₂ from the atmosphere.Sublime Systems uses calcium silicate minerals or industrial waste to produce cement via an electrochemical process—rather than through heating.Cemvision has begun pilot production of fossil-free cement made entirely from recycled materials.This Swedish company doesn’t use raw limestone or fossil fuels—it instead recycles byproducts from mining and steel production, reducing energy consumption and eliminating waste altogether.The company has designed its cement to be "plug-and-play," meaning it can be seamlessly integrated into existing structures alongside conventional cement, enabling rapid adoption.3. Fuel Transition and ElectrificationFuel switching and electrification are critical for reducing energy-related emissions.Using decarbonized electricity to partially heat the kilns used for clinker production, and replacing fossil fuels with low-carbon alternatives for heating the remaining portion, can help phase out coal gradually.CoolBrook, SaltX, and Rondo Energy have all developed alternatives to fossil-fuel-based kilns and calciners—powered by electricity or heat—that preheat limestone before it enters the furnace.Another way to achieve the extremely high temperatures required is concentrated solar power, a technology that has already been tested by startups such as Synhelion (in collaboration with Cemex) and Heliogen.Low-carbon fuel alternatives are also common in other industries, ranging from short-term, interim solutions—such as biomass and plastic waste—to longer-term options like green hydrogen.Point-source carbon capture is a key method for reducing emissions from the cement and concrete industries—specifically, it involves capturing and storing carbon dioxide emitted by large sources such as power plants and industrial facilities, preventing it from being released into the atmosphere.According to forecasts from the Global Cement and Concrete Association, carbon capture, utilization, and storage could cut carbon emissions by 36%, making it the single biggest lever for reducing emissions in the cement industry.Norway's shipping town of Brevik has become the first place in the world to host a cement plant equipped with carbon capture and storage technology.Heidelberg Materials' 100-meter-high carbon capture and storage facility began installation in August and is expected to be completed by the end of 2024.It will capture the carbon dioxide generated during the clinker production process, preventing the gas from being released into the atmosphere—and the carbon will be safely stored underground in the North Sea.Net-zero cement productionAt last year's COP28 conference in Dubai, countries agreed to launch the "Cement and Concrete Breakthrough" initiative, aiming to establish and scale up near-zero-emission cement production across regions worldwide by 2030.To achieve this goal, it is crucial to widely adopt the four innovative cement and concrete production processes mentioned above.

The above content solely represents the author's personal views.This article is translated from the World Economic Forum's Agenda blog; the Chinese version is for reference purposes only.Feel free to share this on WeChat Moments; please leave a comment below the post if you’d like to republish.

Editor: Wang Can

The World Economic Forum is an independent and neutral platform dedicated to bringing together diverse perspectives to discuss critical global, regional, and industry-specific issues.

Follow us on Weibo, WeChat Video Accounts, Douyin, and Xiaohongshu!

"World Economic Forum"